These are not light duty watchmaker's lathes, but can hog off respectable amonts of mild steel without problems.

10 Nov update..

I talked with a Taig dealer who said that the replacement knob will not fit this lathe as they changed it after this one was born. No problem though, i just ordered a complete cross slide screw assembly that has the new dial and knob for under 25 bucks. Reasonable for me. Future posts til it arrives will be cleaning and oiling....

End result is a convincing can.

It has a one year history of use and a 10 year history of sitting unused. It came with a number of add on accessories that will really add to it's potential. In addition to the normal package it came with a 4 jaw self centering chuck, Jacobs tail chuck that fits over the dead center on the drilling tailpiece. It also has the milling tower attachment for the cross slide, and some kind of indexint jig attached to it.

Also present is a movable tool rest for wood turning with hand held gouges.

It needs a good cleaning and oiling and remounting to it's base. i am going to look into a powered lead screw option and replace the cross slide knob as it's handle broke off during shipping, an inexpensive replacement. There are a number of modifications depicted online showing larger handles that rotate around the mounting bolt that would make it easier to operate. I will look into those as well as some replacement handwheels from Sherline that have a resettable dial.

This is going to be a help and a distraction to my miniature builds, but oh well.... =)

10 Nov update..

I talked with a Taig dealer who said that the replacement knob will not fit this lathe as they changed it after this one was born. No problem though, i just ordered a complete cross slide screw assembly that has the new dial and knob for under 25 bucks. Reasonable for me. Future posts til it arrives will be cleaning and oiling....

17 Nov update...

The new screw assembly arrived and went in easily. I went ahead and set the lathe up in a temporary location, my shop being all discombobulated so contractors can wander in and out.

One of the first reasons I got this was to do cans for the store roombox, so I chucked a piece of aluminum up and this is the result;

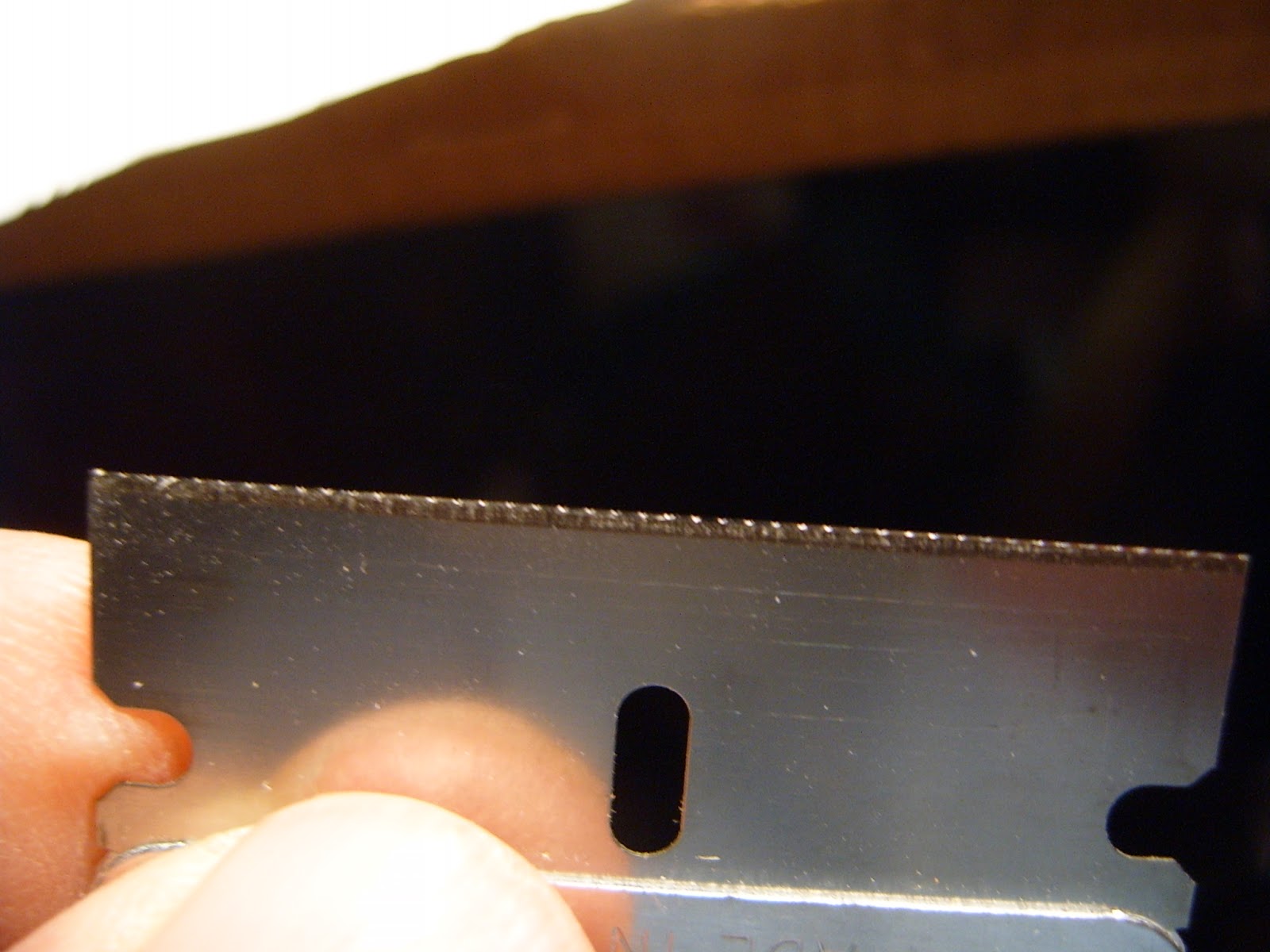

Both end shoulders turned at same time, then cut off, and wrapped in tape to level out for rechucking.