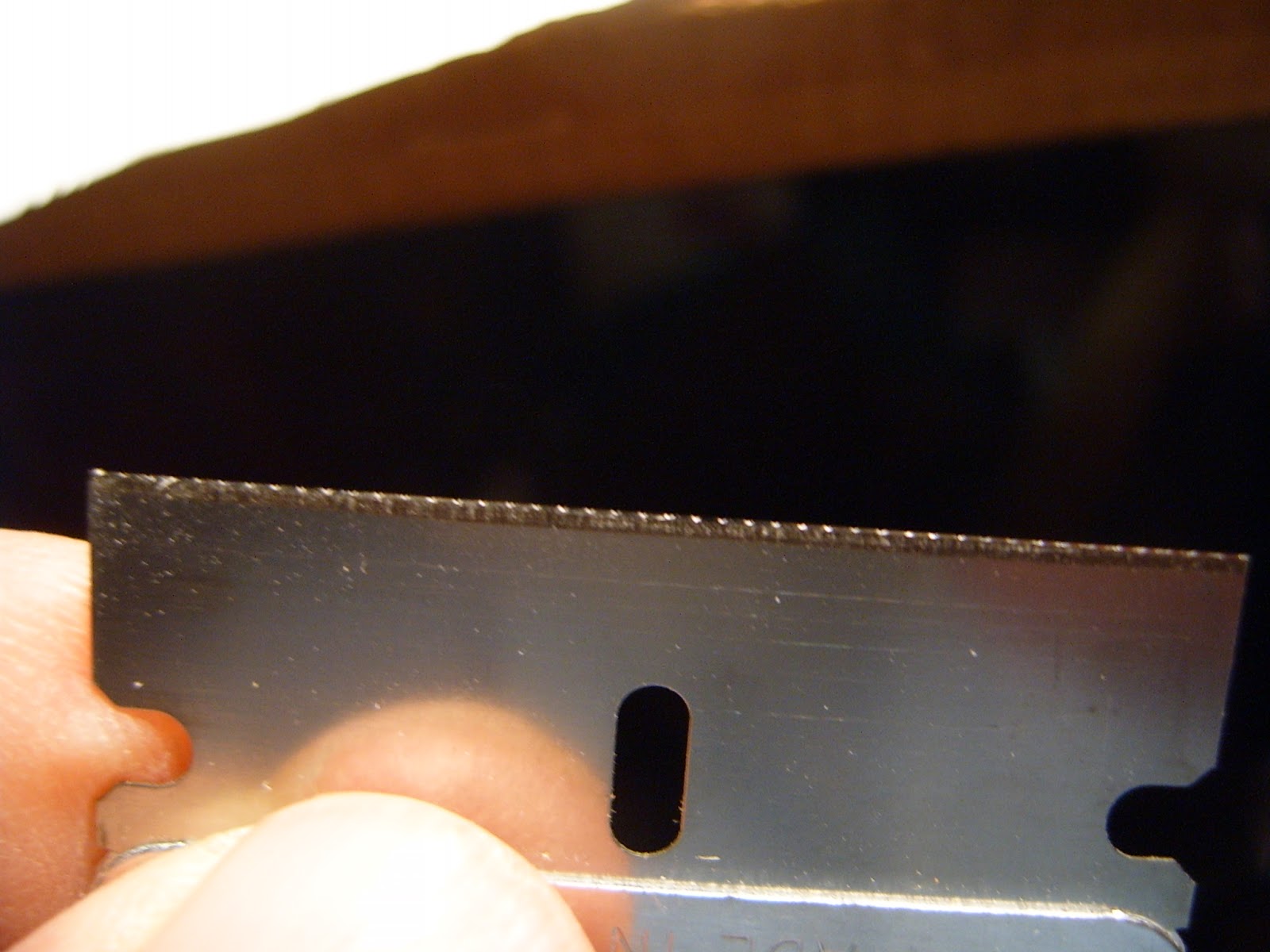

I have a large box of single edge razor blades and decided to try converting one or more into some sort of saw blade.

The technique I used turned out to be very successful in creating teeth that cut a very thin kerf. The blade's body measures 0.008", and the cutting edge is considerably thinner than that. I clamped the blade in a small clean faced vise and tapped the protective cover flush with the top of the blade body inside.

I then took a set of forceps and a large metal file and holding the blade with the forceps at a 90 degree angle to the file teeth, resting on the file, I struck the top of the blade with a hammer which left regular sharp dents in the cutting edge which work very well as a saw.

The first was a fairly fine file which left fine teeth.

I tried this as well with mixed results, clamping a fence along the direction of the teeth on a rusty file, then dragging the blade across the teeth. I was able to do this more than once since the teeth registered with the teeth on the file. I still have better results striking with a hammer though.

No comments:

Post a Comment